Company Product Introduction

Zhangjiagang Longsn Machine Co., Ltd. is a professional manufacturer specializing in high-speed automatic cap aluminum foil/foam seal liner inserting machines. We provide custom solutions for various cap sizes and sealing requirements. Our products are widely used in industries such as food and beverage, cosmetics, and healthcare. Contact us now to learn more about our efficient sealing solutions!

Pre-Cut Cap Lining Machine Specifications:

Parameter | Value |

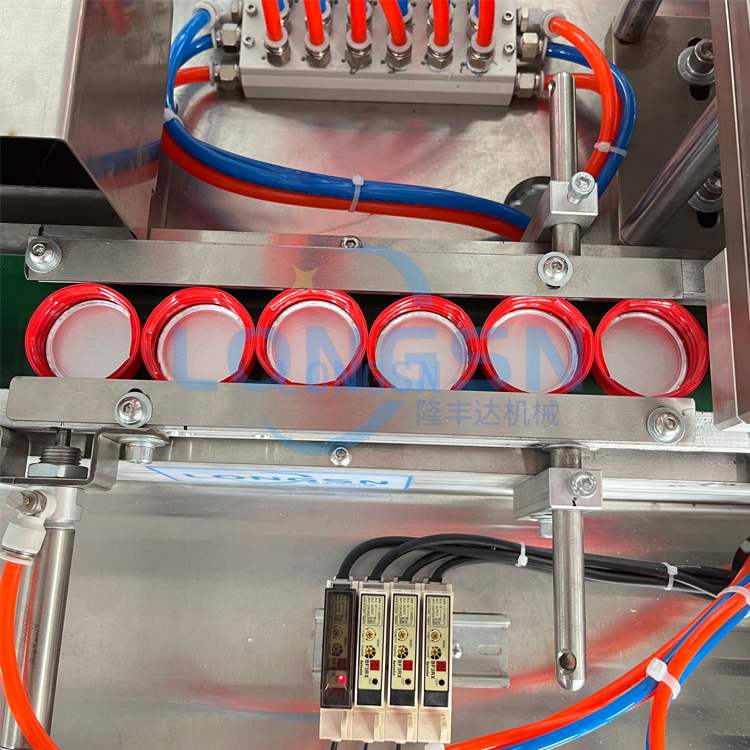

Model | LSN-L6 |

Cap Size | 15mm-120mm (customizable within this range) |

Electric Supply | 110-220 VAC, 1 Phase, 50-60Hz |

Speed (Output) | LSN-L1: 40-60 caps/min; LSN-L2: 80-120 caps/min; LSN-L6S: 160-200 caps/min |

Wad Thickness | 0.2mm-1.0mm |

Wad Types | EP foam, Induction wads, Liners, Aluminum foils |

Application Range | Cleaning products, Detergents, Cosmetics, Beverages, Skincare, Dairy, Hair care, Oils |

Packaging Material | Plastic |

Control Mode | PLC + Touchscreen |

Shipping Package | Wooden crate |

Brand | LONGSN |

Our LSN-L series standard cap lining machine inserts induction wads/ liners in caps from pre-cut liners. Among the various types of cap wadding machines, we have different models of machines that are convenient for every production need, such as: Production Rate, Sizes and Shapes of caps.

This cap lining machine working principle:

The caps will be stacked into a Vibratory or Elevator Hopper physically then the feeder supplies the caps satisfactorily as needed to the machine in the arranged style.

The cap tunnel moves the cap to a positioning star wheel where the caps are filed at predefined areas.

The wads are stacked into a store tunnel (in same direction) or into a vibratory feeder (for loosely packed liners, ordinarily for EPE or Foam liners) which is set over the wad picking station.

The vacuum picker loading machine is set beneath the section chute which picks the wad individually and places it on the top segment of the ordering star wheel over the caps. At the point when the cap and the wad moves to the following station a pusher drives the wad into the cap and is immovably fixed.

The gathered cap will be tallied and will get out from the conveyor and defective cap(without liner) will be detection and rejected out.

The cap lining machine will be fit for taking care of different kinds and sizes of caps and wads with the assistance of changing parts in a allow range.

Product customization service

Base different customers will have different requirements , so on our cap lining machine you can also have follow additional optional :

Hot melt glue injection system : sometimes some special caps will need injection a small hot melt into cap first before insert into the liner , so for this type cap we can additional install the hot melt glue injection system onto machine.

Vision inspection system : sometimes customers have a high requirements on the caps quality , no only need have liner inside but also need caps no broken/no spot /no foreign matter , then we can install a vision inspection system at the machine output conveyor place to do these detection.

We have diferent models Wad Inserting Machine , and hot sale model stations with Single Head(LSN-L1), Double Head(LSN-L2) and SIX Head(LSN-L6S). These LSN-L1 and LSN-L2 model heads use vacuum to pick and place pre-cut liners/wads from a magazine into the cap. LSN-L6S model machine is special for thick type liners(thickness more than 0.5mm) and which will use pushing pressing type device to insert liner into caps . A few discretionary worth added highlights are accessible to improve product quality.

So if you have a need of the auto cap lining machine then please feel free to contact us , we are the professional experience and one of the biggest manufacturer in China for these machines , we can give you a best solutions for your caps projects .

All of our teams looking forward to work with you and service for you ! Thank You !

English

English