Machine Features:

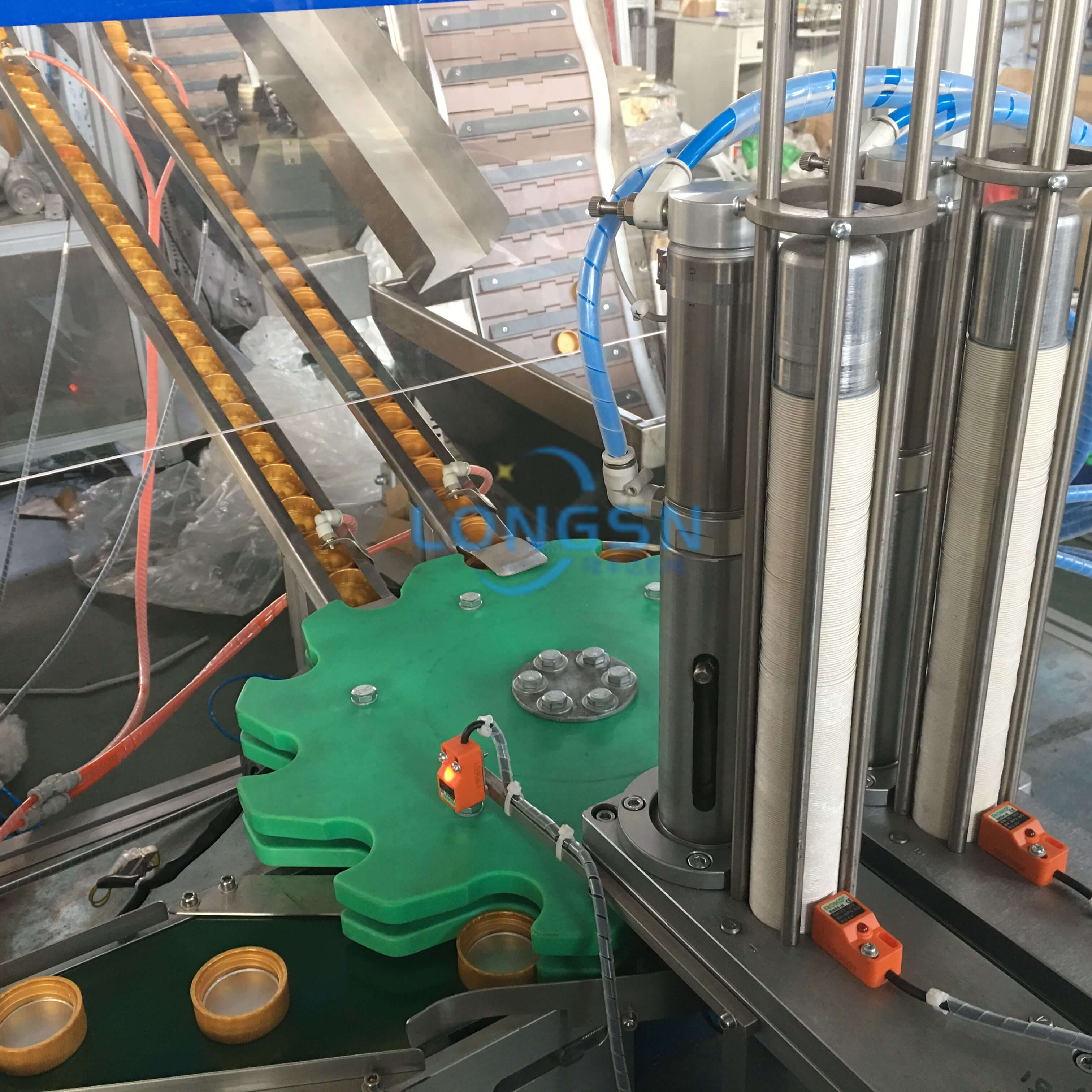

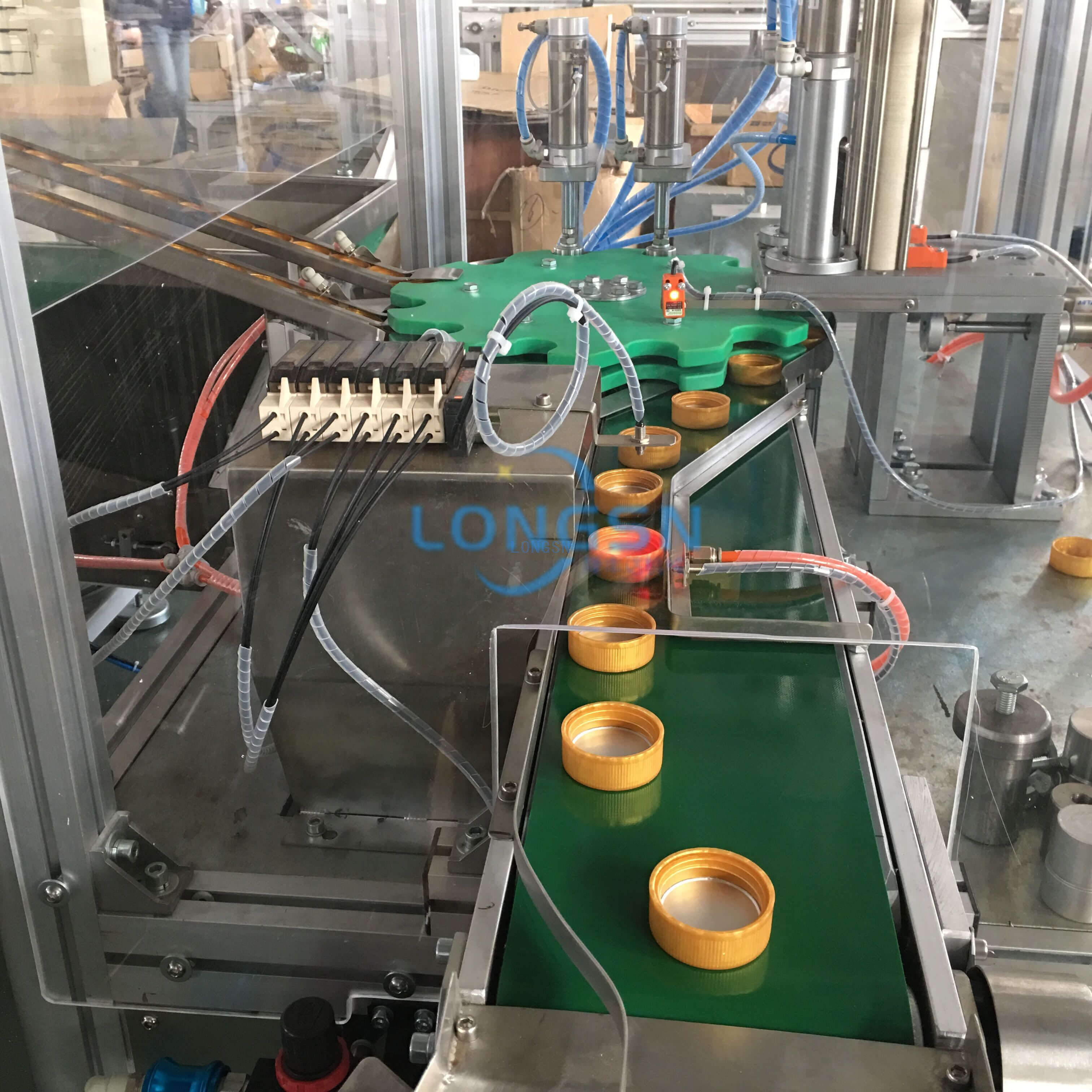

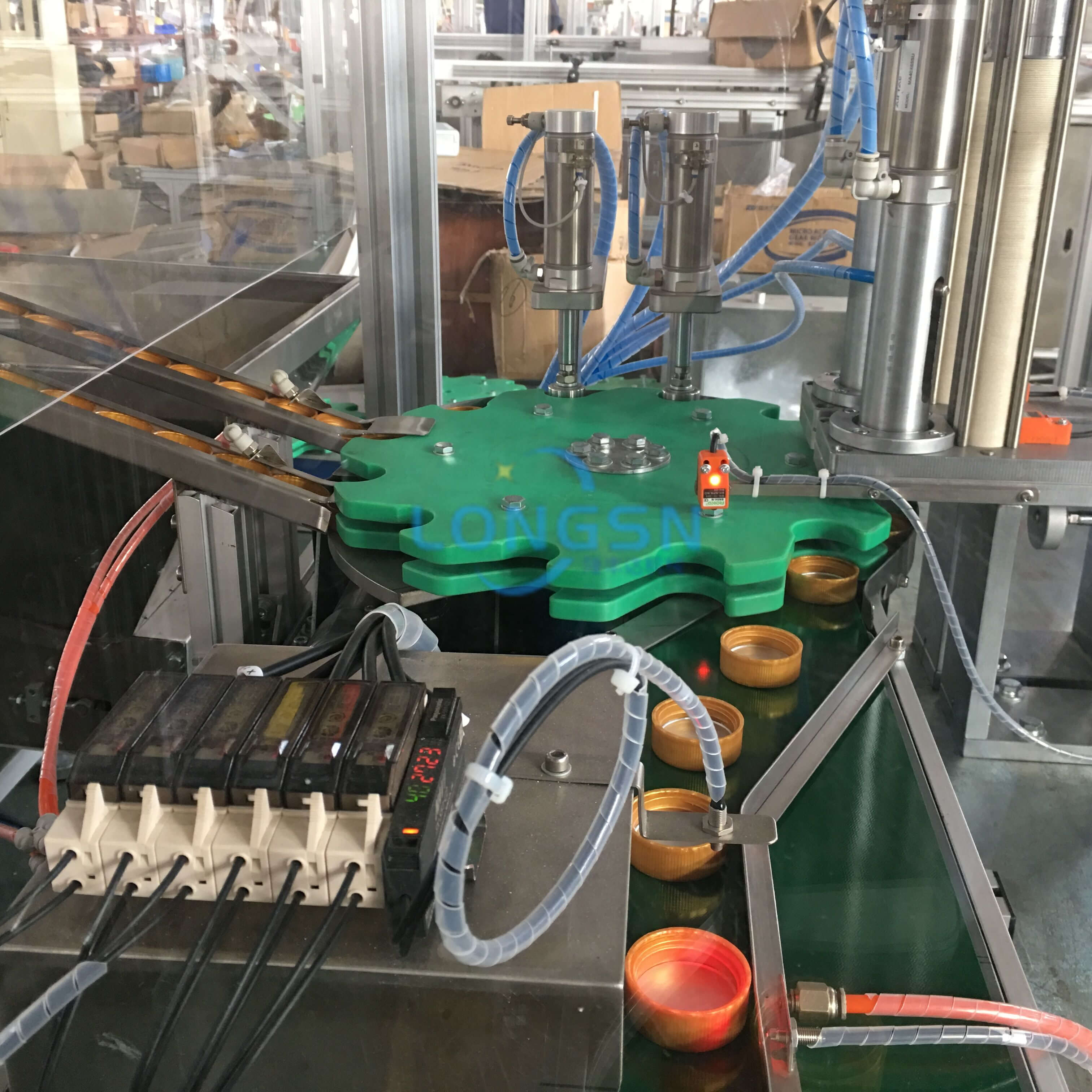

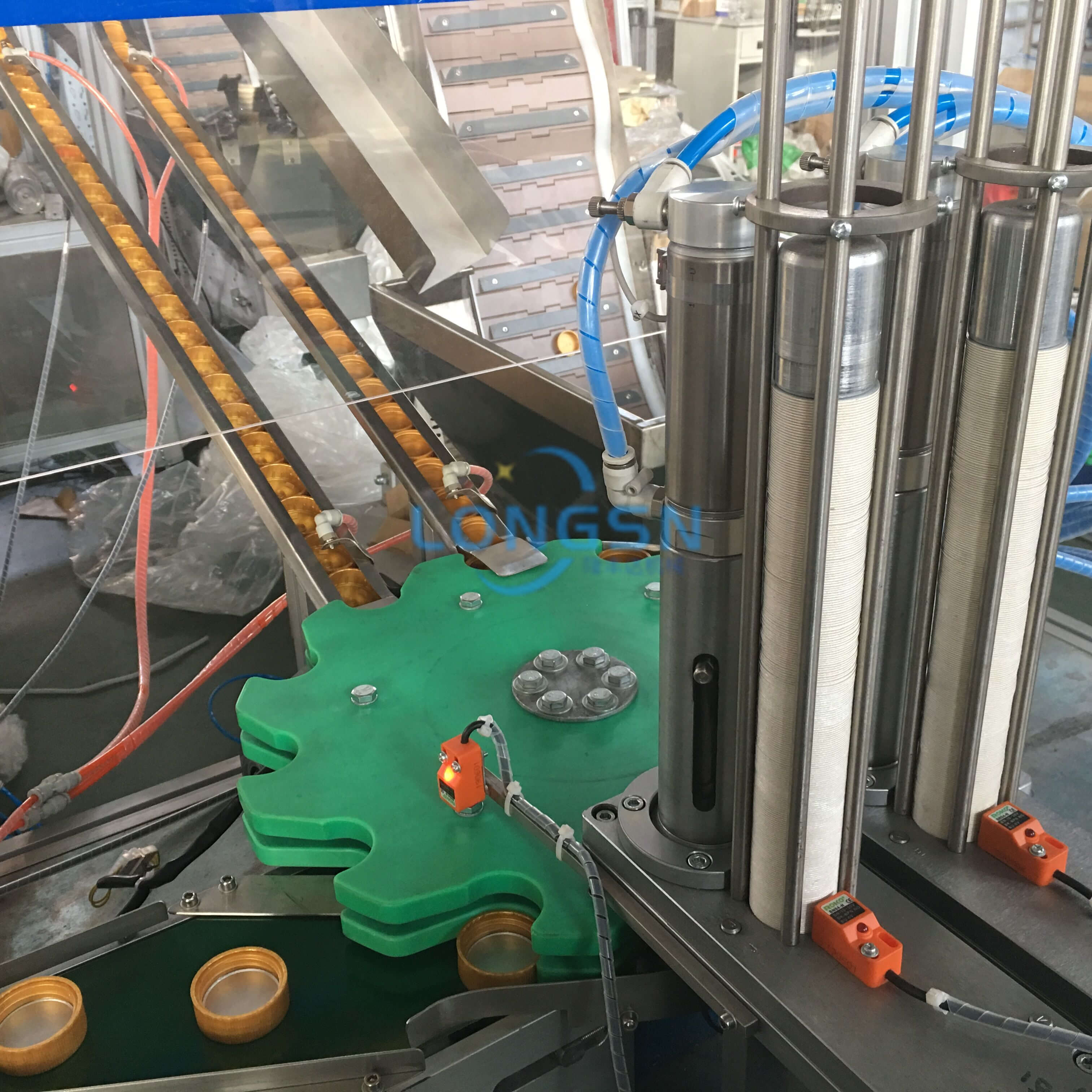

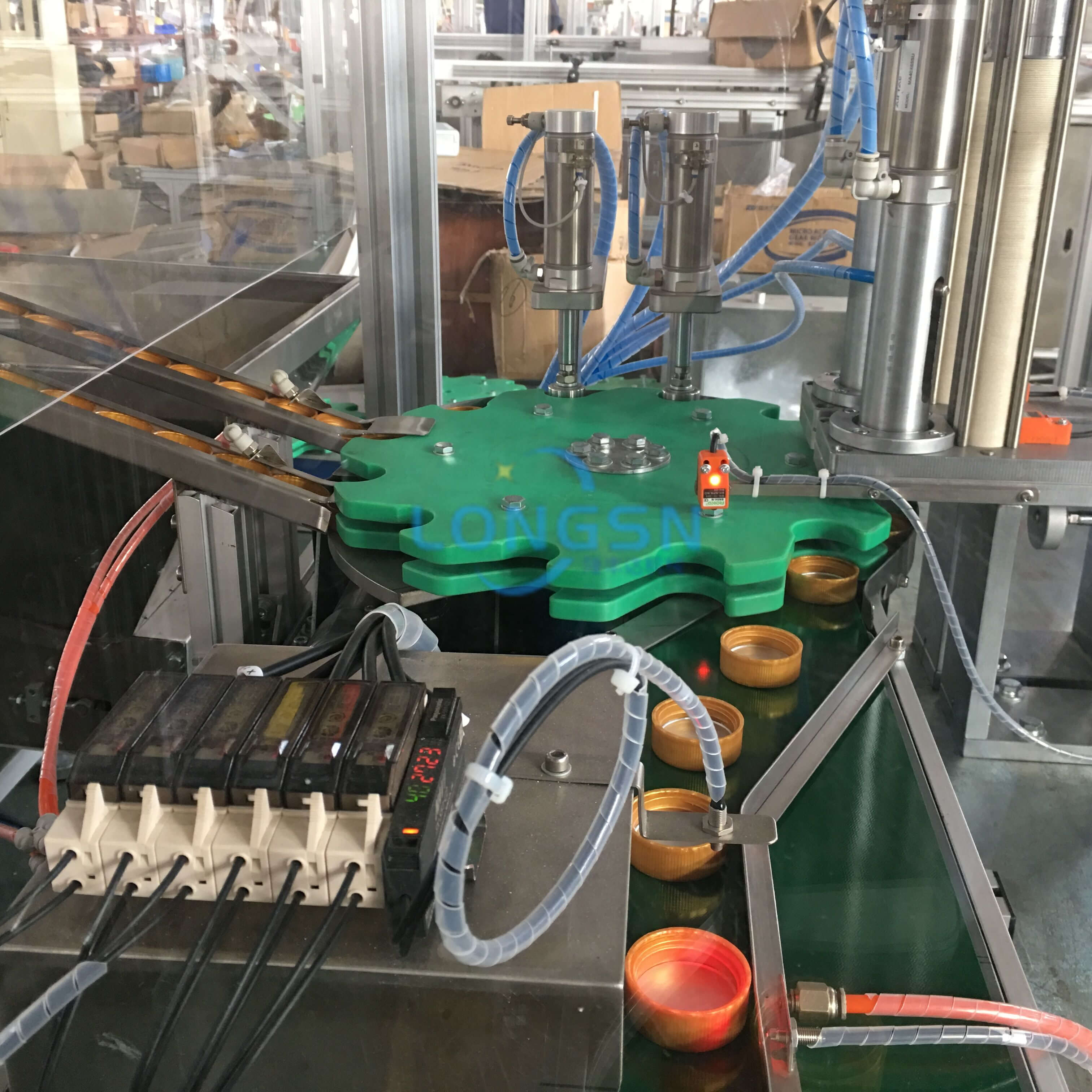

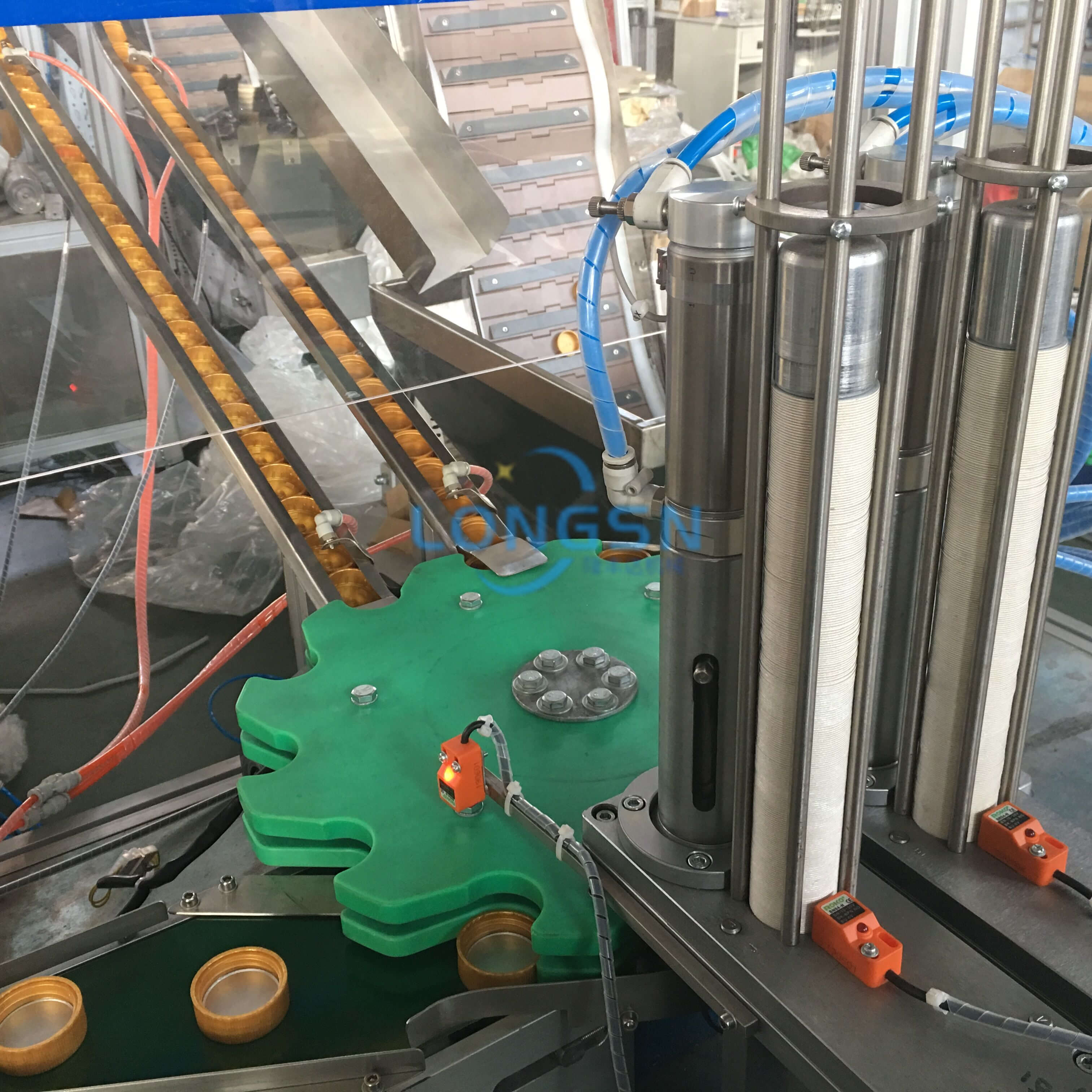

1. Automatic cap assembly and inserting have replaced manual work, which substantially raises the work efficiency.

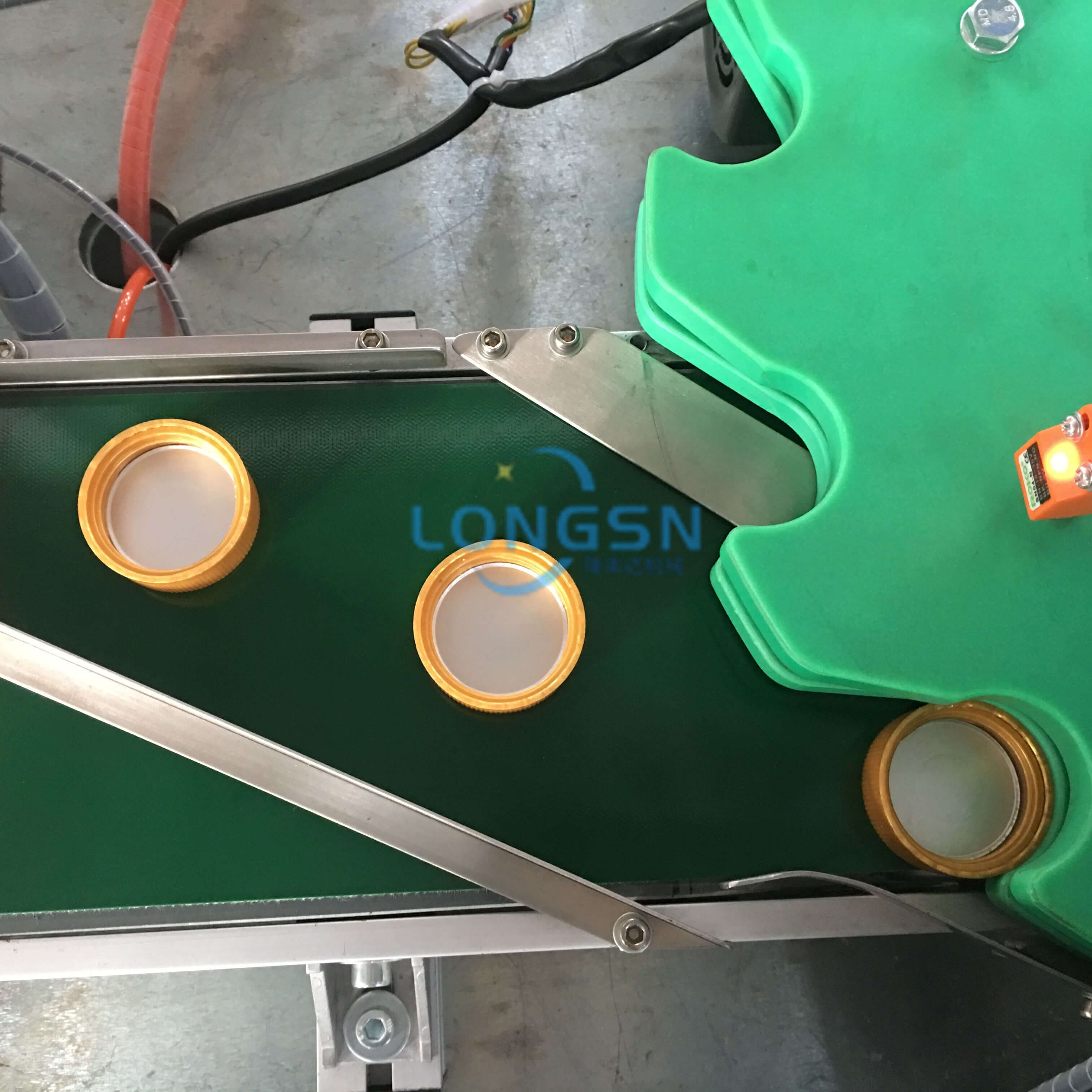

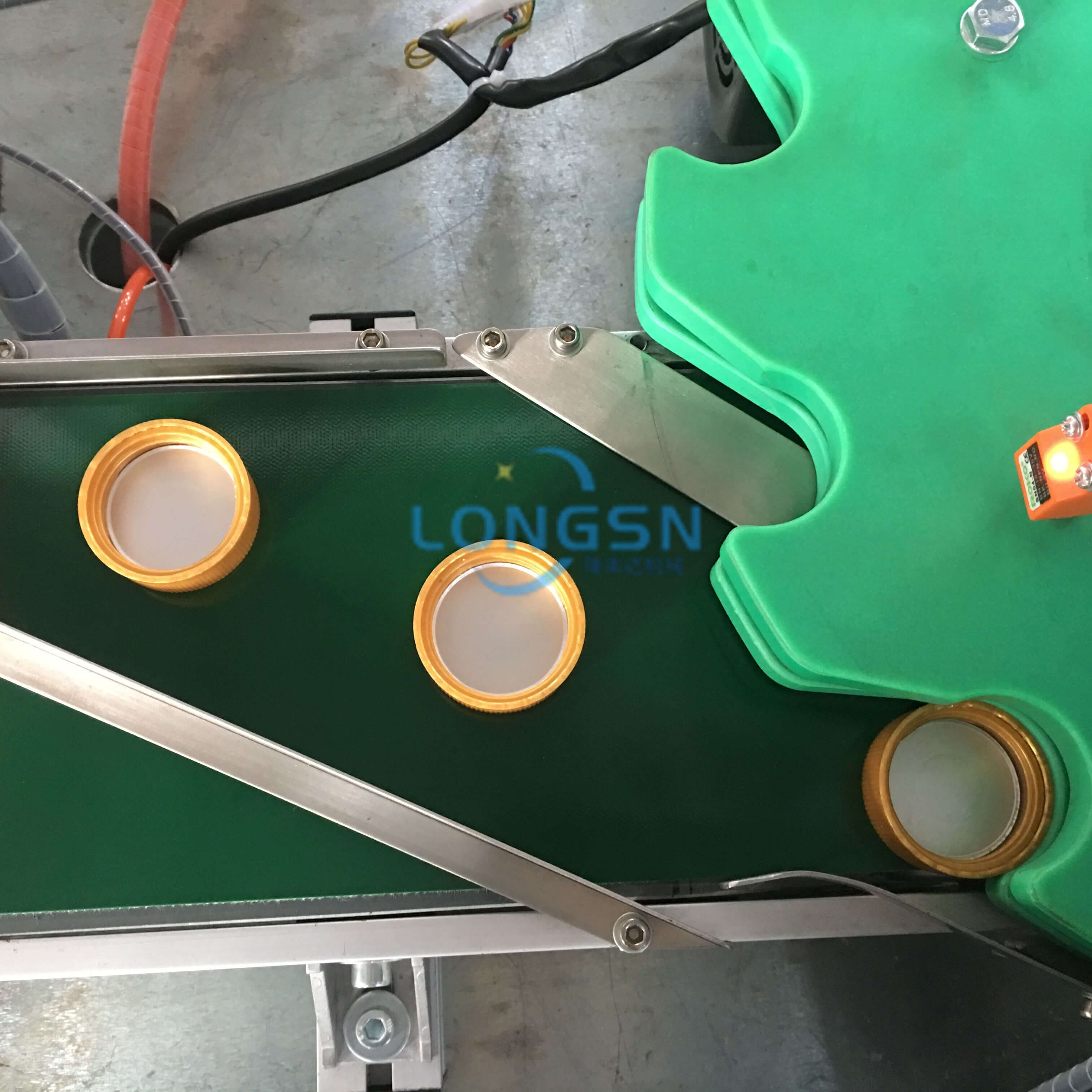

2. Liner inserting features good accuracy, high speed and high efficiency; the bottom is smooth when the liner is stamped into the cap without upwarp; finished products have good appearance and standardized quality.

3. The machine will stop automatically when there is no material feeding: the machine alarms and stops automatically when there is no cap on the cap conveyor belt or when there is no liner material.

4. The machine has automatic count function. The machine can stop automatically according to the set number of caps, or an outlet direction converter of conveyor belt can be equipped; when the number of caps reaches that set by the user, the converter will automatically convert the outlet to another box.

5. The operation of the machine is controlled by imported PLC, with touch screen operation and people-oriented design. All functions can be operated and set on the touch screen, simple and convenient.

6. Through our company’s independent research and development, the whole machine is designed with mechanical transmission, and parts have applied pneumatic accessories. The design of automatic lubrication system guarantees stable operation of the machine and prolongs its service life.

7. When caps are of different sizes, the replacement of liner stamping mould, turnplate is simple and convenient.

8. The machine is an automatic packaging device designed and manufactured by our factory in strict accordance with national GMP standard and technological requirements. Our safe and sanitary products can avoid secondary pollution of materials and omit the sterilization process, especially suitable for occasions with strict sanitary requirements

9. It can get rid of bad products automatically .

Electric appliance :

1 | Main electronic parts | SIEMENS |

2 | Electric protection switch | SIEMENS |

3 | Circuit breaker | SIEMENS |

4 | PLC | MITSUBISH |

5 | Touch screen | WEINVEW |

6 | Transducer | MITSUBISH |

7 | Photoelectricity switch | AUTONICS |

8 | Pneumatic element | AIRTAC |

9 | Pressure sensor | SMC |

10 | Motor | SIEMENS OR ZHONGDA |

English

English