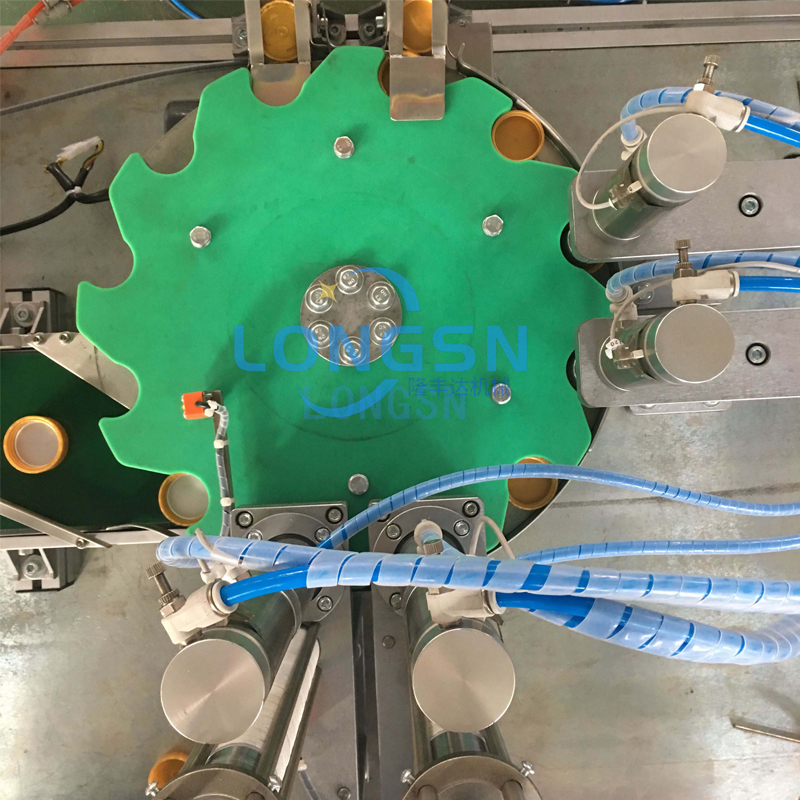

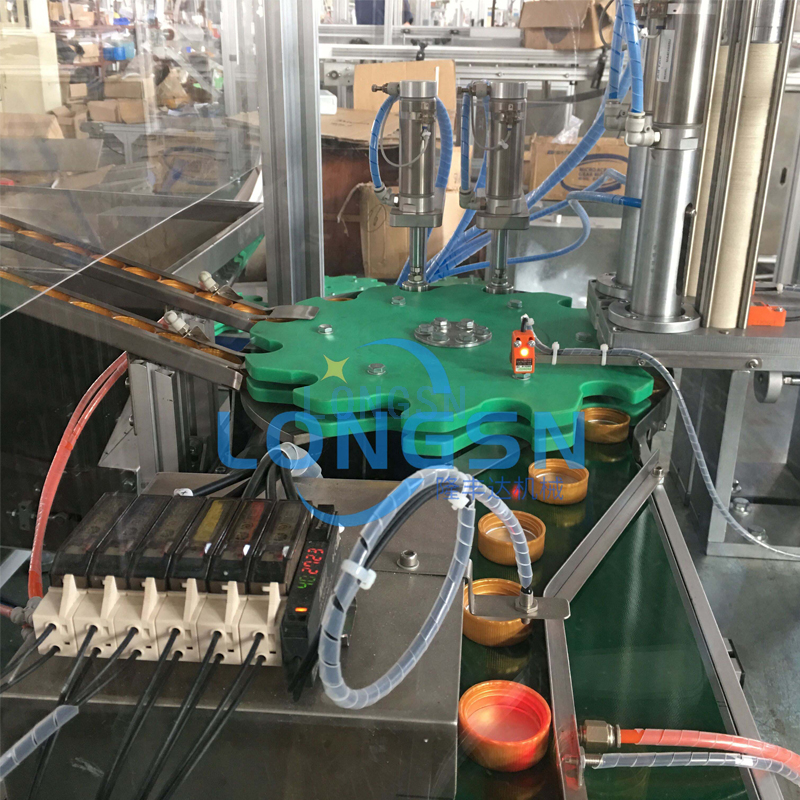

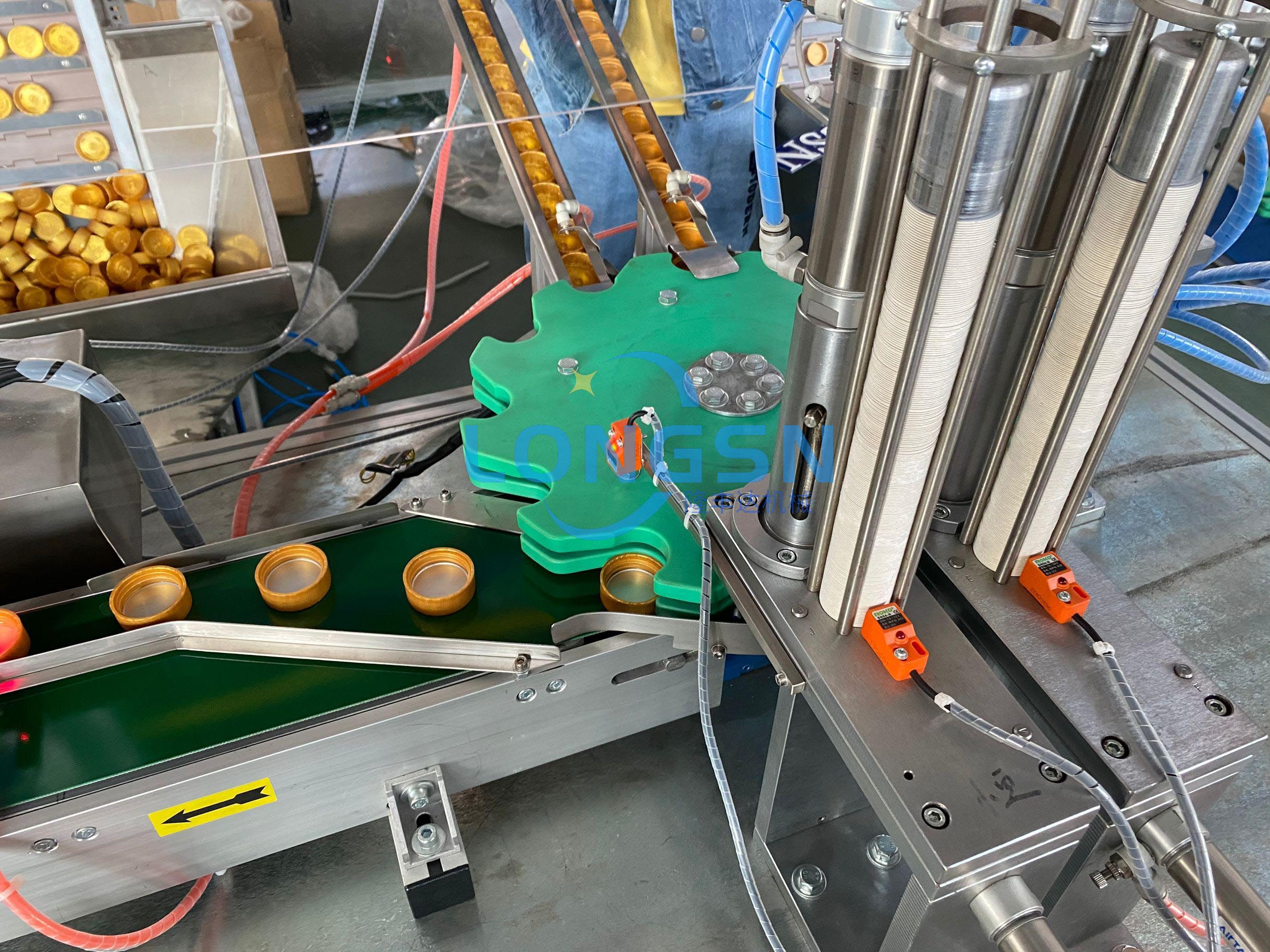

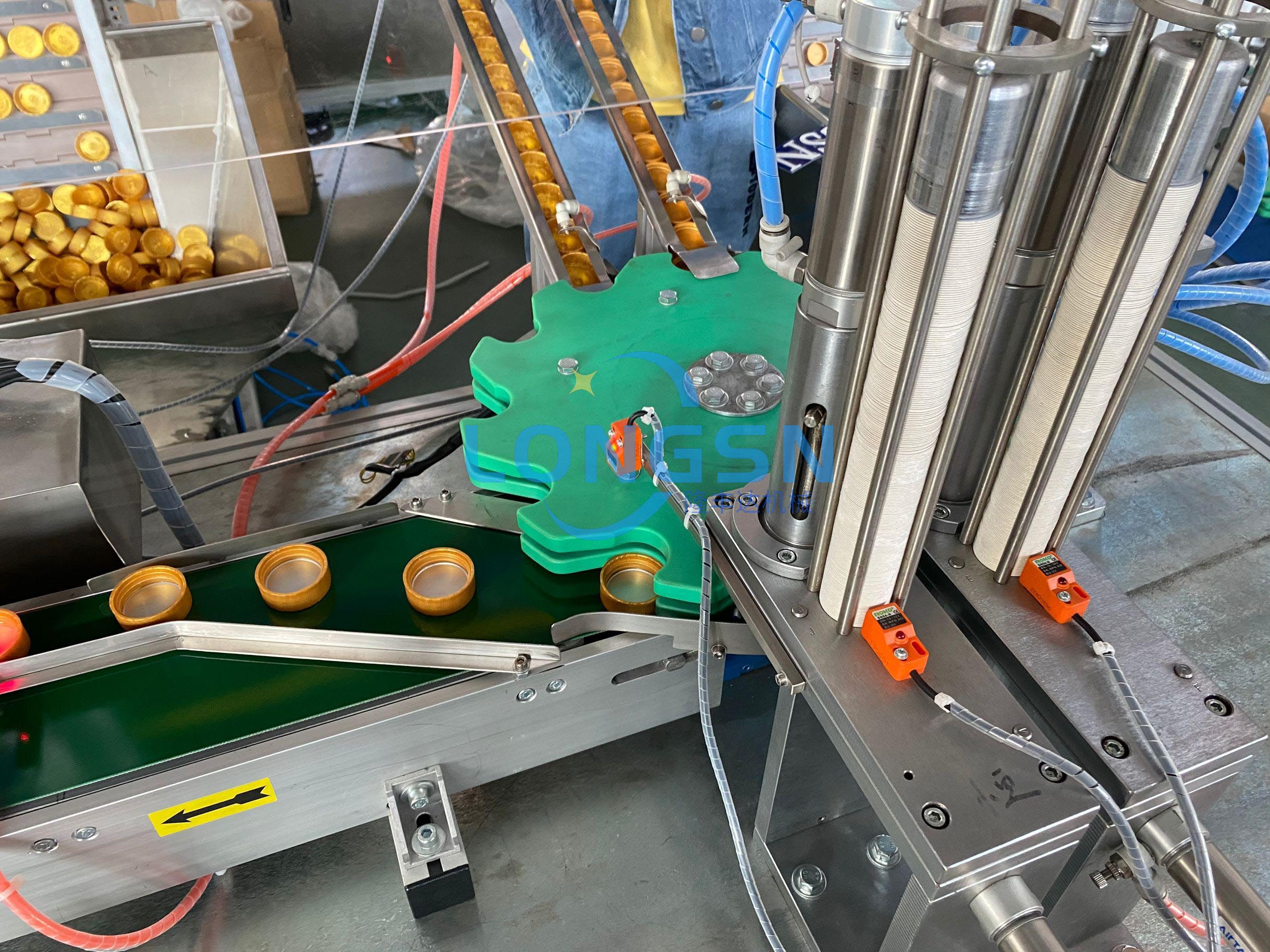

Automatic Bottle Cap Liner Lining Assembly Machine

Original Japan PLC control, man-machine interfere,intelligent recognition of defective products are automatically rejected. Production figures can be set. When automatic alarm is on it can shut down.

a. This machine replaces the handwork. It automatically inserts the liner into the bottle cap, and can raise work efficiency greatly.

b.Reasonable Liner Sealing, Fast speed, High efficiency, Safe and Sanitary product.

c. Suitable for situation which requests the hygiene condition strictly, avoiding second pollution to the material, economizing a disinfectant craft;

d. Sorting Cap System attaches the function of cap elimination, in order to make sure every finished bottle cap upward.

e. Transfer and transport the cap and accurate targeting system;

f. The whole machine adopts PLC to control. If there’s no chip, no cap, it will alarm;

Technical parameters:

| Model | LSN-AL2 |

| Speed | 3000-8000pc/h(CUSTOMIZED) |

| Size | 2500*1850*1800mm |

| Air pressure | 5-7kgf/m2 |

| Weight | 580kg |

| Power | 220V 50-60Hz |

Electric appliance of our machine(can adjustment)

1 | Main electronic parts | SCHNEIDER/FRANCE |

2 | Electric protection switch | SCHNEIDER/FRANCE |

3 | Circuit breaker | SCHNEIDER/FRANCE |

4 | PLC | MITSUBISHI/JAPAN |

5 | Touch screen | WEINVEW/TAIWAN |

6 | Transducer | SCHNEIDER/FRANCE |

7 | Photo electricity switch | AUTONICS/KOREA |

8 | Pneumatic element | AIRTAC/TAIWAN |

9 | Pressure sensor | SMC/JAPAN |

10 | Motor | ZHONGDA /CHINA |

Packaging & Shipping & Payment:

| 1 | Delivery time: | 30-40 days since receive deposit & samples |

| 2 | Shipping: | By sea or by air |

| 3 | Packaging: | Standard exported wooden cases |

| 4 | Payment: | T/T, Western Union, Confirmed LC at sight; |

| 5 | Payment term: | 30/40% deposits, 70/60% balance before shipment |

Procedure from order to after-sale service:

| 1 | Inquiry-Professional quotation. |

| 2 | Confirm the technical layout, price, lead time, payment term etc. |

| 3 | Freedom sales send the proforma invoice. |

| 4 | Customer makes the payment as deposit and sends us samples |

| 5 | We start manufacture machines. |

| 6 | Middle Production-send photos to show the production line which you can see your machines in production.

Confirm the estimated delivery time again. |

| 7 | End Production machines photos and videos will be sent to you for approval. You can also arrange to our factory for Inspection. |

| 8 | Customers make payment for balance and we arrange to ship the machines. |

| 9 | Engineer is available for installation or after-sale service in factory overseas. |

| 10 | Feedback to Freedom about Quality, Service, Market Feedback & Suggestion. And we can do better. |

English

English